For all the national introspection around Canada’s housing crisis, far too little attention is paid to the mechanics of how homes are actually built. While we debate affordability, interest rates, and migration, the real constraint on supply lies in the production system itself, one that has failed to modernize in step with the urgency of our needs.

The latest report from the C.D. Howe Institute exposes that friction with sobering clarity. Canada’s housing shortfall, it argues, is not merely the result of low output. It stems from a deeper misalignment between our stated goals: rapid, affordable, large-scale housing and the fragmented, risk-averse, low-productivity methods we use to deliver it.

The housing sector does not lack talent or technology. What impedes us is a model of construction that has remained essentially unchanged while the demands placed upon it have intensified.

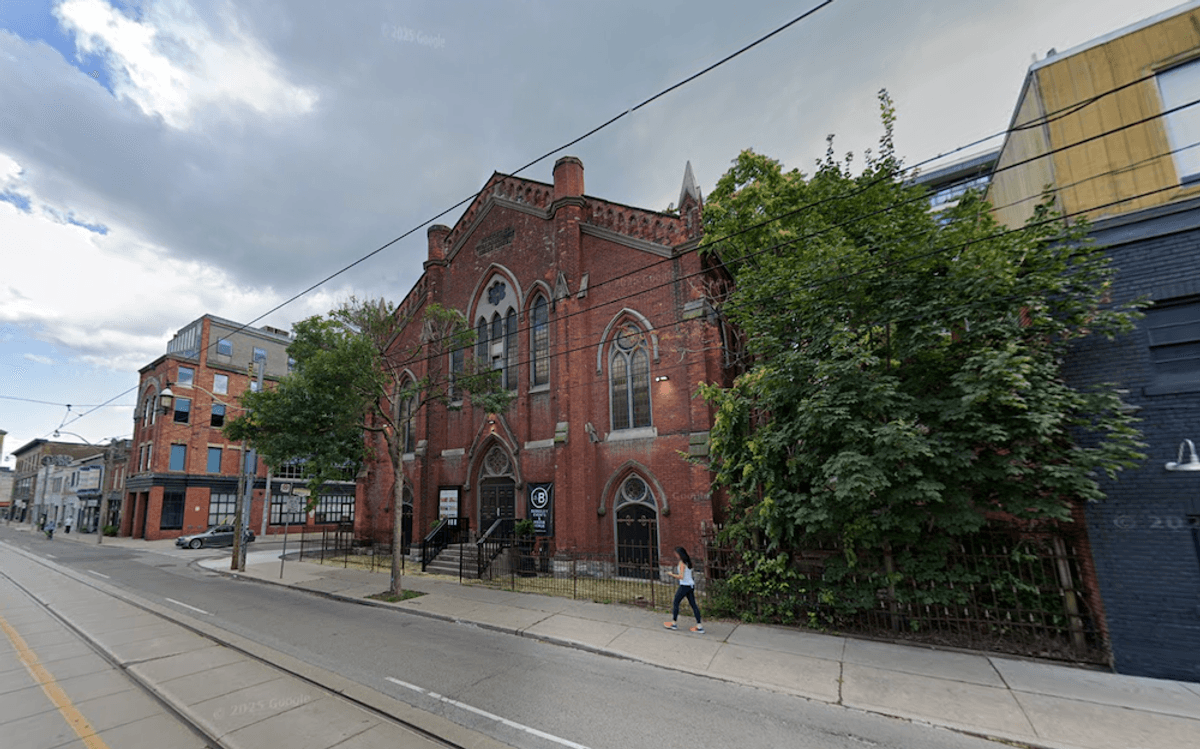

Permitting Purgatory, Before a Single Shovel Hits the Ground

Before we even get to labour shortages or modular innovation, Canada’s pipeline is choked at the municipal counter. It takes nearly 250 days to secure a general construction permit in Canada — 34th out of 35 OECD countries, slower than every peer except Slovakia and roughly triple the US timeline, according to the ICBA Independent.via Valery.ca

That “second-slowest in the OECD” badge isn’t just embarrassing for a G7 economy; it means every policy aimed at speeding up housing delivery starts with a nine-month bureaucratic head-start against us. It is beyond embarrassing for a country that needs housing affordability solutions more than anyone else in the OECD. Until those approvals shrink, any talk of boosting supply is running a marathon in concrete boots. It is possible that standardized construction could deliver just as much benefit to the approval process as it can to the construction process. As the saying goes, time is money, and all of these savings translate to a more profitable housing model, which means greater incentive for builders to build.

Whether you like it or not, firms exist to make profit. That’s how the economy works. It is only fair for you to expect anyone else in the economy to do their job for free if you also do your job for free. Whenever I mention a builder’s profit and savings like this, especially when discussing removal of development charges, people tell me that builders will just pocket the spread. In a historically “normal” market jacked up on cheap debt, I might agree with those people. But in today’s market, any dollar that a builder can reduce from price gets them closer to the market’s bid, which increases their likelihood of selling or renting a unit. So, I can promise you, if builders save $50,000 on any input today, they’re not going to keep the unit priced at $750,000 so they can keep selling zero units. They’ll drop the price by $50,000 in hopes that they sell one, or two.

Ambition Without Capability

According to the report, restoring 2019-level affordability would require between 430,000 and 480,000 new homes per year. In 2023, Canada built just over half that number. The gap is profound, and there is little to suggest it will close under present conditions.

What makes this deficit even more stark is the rapid growth of the population. CMHC’s own data confirms that housing starts are not keeping up with demographic pressure. The imbalance is especially acute in urban centres but increasingly visible in smaller communities as well.

via Valery.ca

The visual makes clear what many feel in practice. There are simply not enough homes per person. The decline in dwellings per 1,000 residents reflects a structural shortfall that cannot be corrected without addressing the speed and scale of delivery.

Labour Inputs Alone Will Not Save Us

In a healthy system, hiring more workers should lead to higher output. But the data tell a different story. Between 2020 and 2023, the residential construction workforce expanded by 26%, yet productivity declined. More labour has translated into fewer completed homes per hour worked.

The Silver Tsunami: Replacing a Generation of Builders

Canada’s construction workforce is staring down a demographic cliff. Roughly 245,000 skilled workers, about one-fifth of the 2022 labour force, will retire by 2032, according to BuildForce Canada. That translates into nearly 300,000 new hires once population growth is factored in. Unless we industrialize more of the build process, every apprenticeship program in the country could run flat-out and still fail to plug the gap.

- Capacity drag: Even if municipalities issued permits at record speed, projects would stall for lack of crews.

- Knowledge drain: Decades of practical lore (how to pour a winter slab or sequence trades in a 600 sq-ft condo shell) walks off-site with each retirement.

- Cost pressure: Scarcity bids wages higher, so any productivity we can automate or prefabricate is a direct defence against spiralling budgets.

via Valery.ca

This trend is not incidental. The report attributes much of the productivity decline to the sector’s continued reliance on on-site building practices, which remain vulnerable to weather delays, sequential scheduling, and rising labour costs. While much of the economy is automating and digitizing, residential construction has remained wedded to workflows developed in another era.

The Tools Exist. The System Rejects Them.

Elsewhere in the world, governments and industry leaders have responded to these challenges with urgency and imagination. Sweden builds nearly all of its homes off-site, relying on factory-assembled components and standardized systems. In Canada, despite strong examples like UBC’s prefabricated Tallwood House, Siksika Nation’s 3D-printed units, and the robotics-enabled housing pilots led by Promise Robotics, innovation remains on the margins.

What explains this disconnect is not technological unreadiness but institutional inertia. Off-site builders face longer permitting timelines, duplicated inspections, and transportation rules that vary so wildly between provinces that modular units often cannot move efficiently across borders. Development fees, which have risen by 700% over two decades, now account for as much as a quarter of a home’s cost. Lending practices still favour traditional, slower projects, as financing is tied to on-site construction milestones that modular builds cannot easily meet.

The result is a system that rewards convention and punishes speed. In 2024, one of Canada’s leading modular construction firms, Z Modular, closed its Kitchener facility and relocated to the United States, citing overregulation and financing delays. This case should not be seen in isolation. It reflects a broader trend: firms that try to build faster are often forced to leave.

Capacity Is Being Left on the Table

The C.D. Howe report invokes the concept of the production possibility frontier: a theoretical ceiling for how much can be built with current resources. Canada, it contends, is operating beneath that ceiling. The country has the workforce, the materials, and the demand. What it lacks is the coordination to bring them together at scale.

Research from McKinsey supports this conclusion. Modular construction, when implemented systematically, can reduce build times by as much as 50% and lower costs by 20%. These are transformative advantages. Yet in Canada, they remain largely theoretical, held back by misaligned rules and the absence of enabling policy.

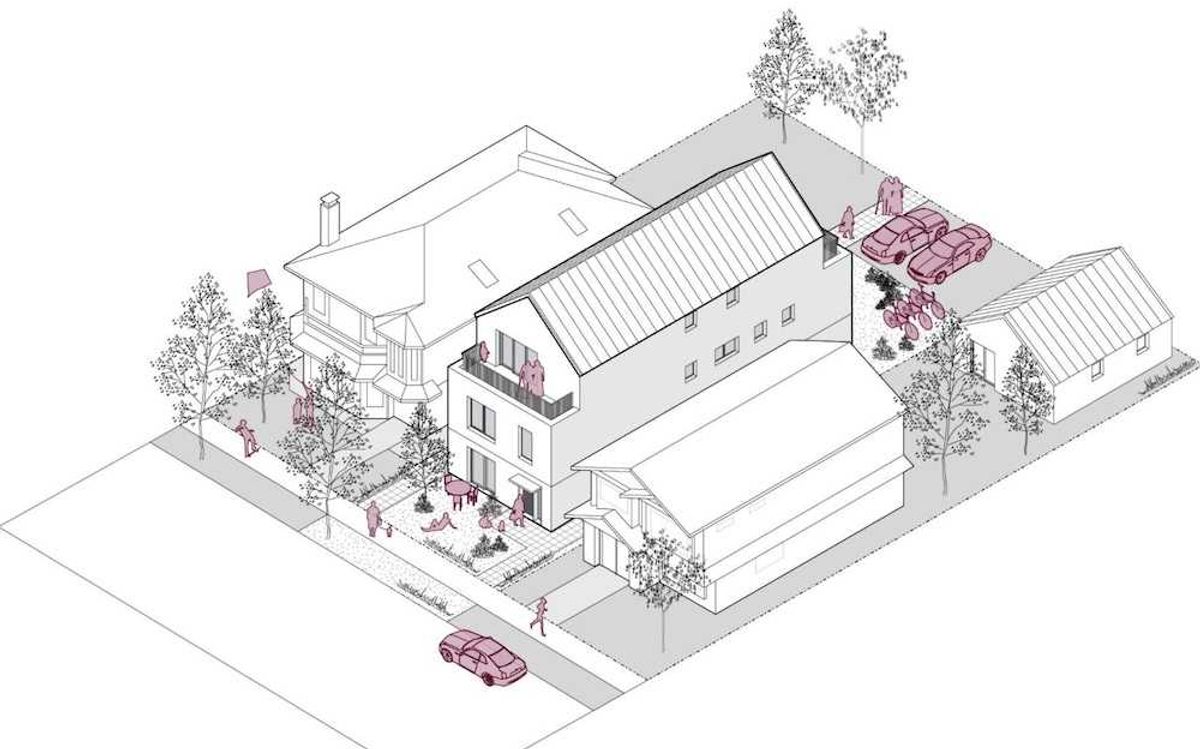

Modular Housing 101: From Panels to Pods

When people hear “modular,” they often picture shipping-container homes. The reality is broader:

- Volumetric (3-D modules). Entire room-sized boxes complete with plumbing, wiring, and finishes arrive on site and are stacked like giant LEGO. Ideal for repetitive layouts such as hotels, student residences, or stacked townhouses. Fastest method, but highway-oversize rules matter.

- Panelized systems. Flat wall, floor, and roof panels are trucked in, craned into place, and weather-tight in a day. Interiors are finished on site. Works well for detached homes or tight infill lots because panels travel efficiently.

- Hybrid or “kit-of-parts.” Think steel or light-gauge frames assembled on site, with factory-built bathroom or kitchen “pods” slid into the skeleton. Balances speed with design flexibility for mid-rise projects up to a dozen storeys.

- Mass-timber / CLT. Large cross-laminated-timber panels (and sometimes volumetric cores) bolt together quickly and cut site noise. Favoured for carbon-conscious mid-rise and urban tight lots.

Different rules affect each approach differently. Policy that treats them all the same will inevitably hamstring at least one. This blog post on Valery breaks down how policy should interact with each modular housing format.

Reform Must Lead, Not Follow

Public investment alone cannot solve this problem. Recent federal initiatives, including the $25 billion Build Canada Homes program and the Housing Design Catalogue, mark a step in the right direction. But they will achieve little without deep structural reform.

Permitting timelines need to be shortened, particularly for projects that use certified off-site methods. Financing models must be updated to accommodate the upfront cost structures of modular builds. Insurance and mortgage eligibility criteria should reflect the reliability of prefabricated systems, not penalize them. Development fees ought to reward faster delivery and lower emissions, not simply size or location. And governments must support the development of a hybrid workforce, one that blends traditional trades with factory technicians, machine operators, and digital designers.

Most crucially, Canada needs real-time productivity benchmarks that compare building methods, timelines, and lifecycle costs. Without that visibility, policy decisions will continue to rely on assumptions rather than outcomes.

The Risk Is Not in Innovation. It Lies in Refusing to Change.

There is no path to affordability that does not run through reform of the construction sector. A system designed for bespoke, site-built housing cannot satisfy the demand of a country adding nearly half a million people a year.

The C.D. Howe Institute’s report offers more than critique. It lays out a pragmatic case for modernizing construction, not through ideology, but through operational clarity. The future of housing is faster, more standardized, and less vulnerable to the constraints of weather, geography, and manual scheduling. The tools are already here. What remains is the will to use them.

Productivity Must Step In for Cheap Money

Statistics Canada’s new Housing Economic Account pegs residential-construction activity at $143.4 billion of GDP and 1.2 million jobs in 2024 — roughly six cents of every GDP dollar. With the post-COVID era of 1-to-2% mortgages gone, that engine can keep turning only if the cost to build drops faster than borrowing costs rise.

Productivity, however, is hampered by chronic under-investment in research:

- United States: US $892 billion of R&D in 2022 — about US $2,600 per resident. (National Science Foundation)

- Canada: C$51.7 billion in the same year — roughly C$1,300 per resident (≈ US $970). (Statistics Canada)

We spend less than half as much on R&D, per capita, as our southern neighbour, yet expect to compete on build speed and cost. If Ottawa wants productivity gains anywhere, housing is the logical beachhead: it is both the largest slice of capital formation and the biggest drag on household finances.

Boosting factory automation, digital twins, and standardized components in residential construction would:

- Lower unit costs, keeping demand alive at higher interest rates.

- Lift wages for tech-enabled construction roles without piling on debt.

- Free capital so the broader economy can diversify beyond housing once today’s supply crunch is solved.

To ignore these findings is not a neutral act. It is a decision to keep building fewer homes, more slowly, at higher cost, while expecting a different result.

CMHC’s Blunt Bottom Line

Ottawa’s own housing agency doesn’t mince words: affordability won’t come back unless we build far more homes, far faster. In its June 2025 report Canada’s Housing Supply Shortages: Moving to a New Framework, CMHC calculates that Canada must double today’s construction pace, raising annual housing starts from roughly 250,000 to 430,000-480,000 units a year through 2035, just to return to 2019-level affordability.

According to CMHC’s chart above, anything short of that keeps price-to-income ratios “near pandemic-era highs,” the agency warns, stressing that “increasing housing supply is the key to restoring affordability.”

Let's not waste another year chasing affordability while preserving the very structures that stand in its way.

Let's begin building as if the crisis is real.

Because it is.