Prefabrication and modular factory-built housing are on the rise in many parts of the world. In light of our current housing supply crisis, we should be embracing these innovative ways of building.

We are in desperate need of new housing and building more prefab and modular units is one way to help tackle the growing problem. By moving in that direction, developers can significantly reduce construction costs, improve quality and productivity, reduce waste and make worksites safer.

Countries like Sweden and Japan are significantly more advanced that us on the modular and prefab front. They have adopted off-site construction to tackle their housing crisis with amazing results.

In Sweden, 84% of the country’s residential construction market share is prefabricated in the shop and then assembled on-site. The country is widely regarded as the global leader in off-site modular construction.

A country-wide, performance-based code has been adopted in Sweden that makes it easier for factories to build homes. The new rules mean the specs are the same for every municipality. They can choose whatever structural system makes sense for their operation, as long as it passes a code check.

Lindbäcks Bygg has invested in automation and cutting-edge technology and assembly line robotics to produce over 25,000 sq. ft of turnkey housing per week. Lumber company Derome also changed its business model to efficiently produce prefabricated building components.

In Japan, meanwhile, about 15% of the country’s new homes are now manufactured off-site. Poland, a recent arrival on the scene, now builds and ships units to hotel developments in other countries.

Sekisui Hiems, one of the largest prefabricated manufacturers in the world, operates many factories across the country, building 14,000 new homes each year -- on assembly lines much like car manufacturing.

We must follow their lead.

If we emulate their approach and make use of modern manufacturing and building techniques that allow homes to be built faster and with fewer workers, it would help boost our housing supply.

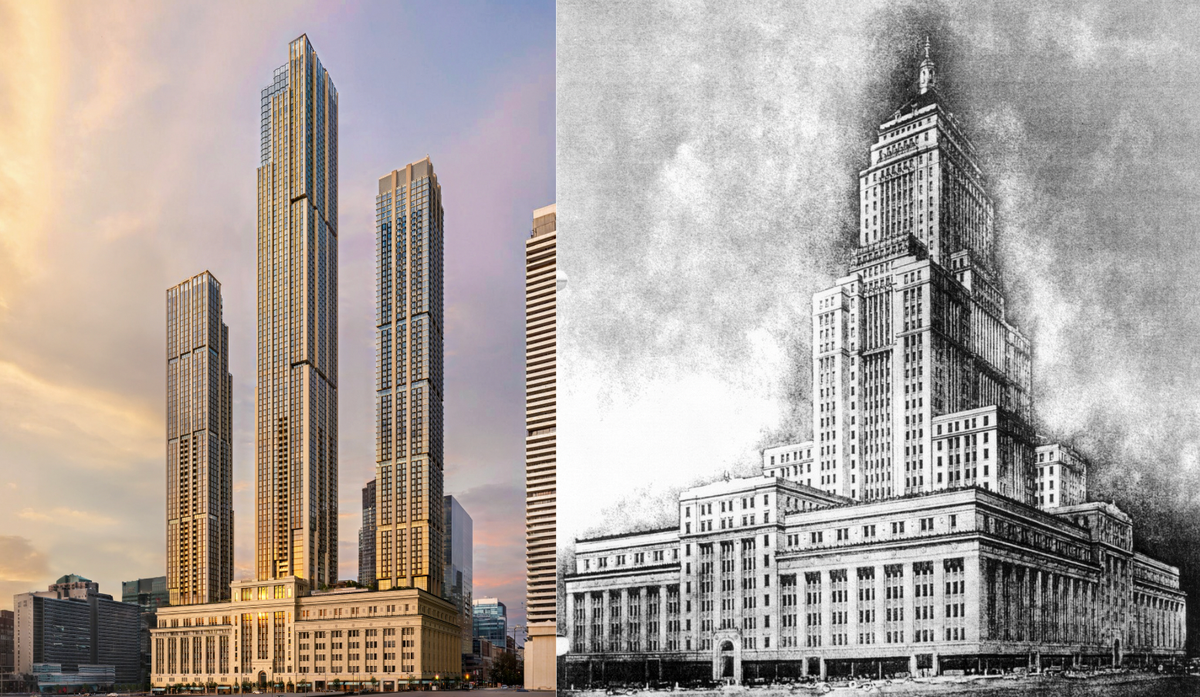

I recently had the opportunity to learn more about some of the latest innovations in modular construction at the recent annual conference of the Council on Tall Buildings and Urban Habitat in Chicago.

One of the unique ventures highlighted was a 50-storey modular housing project built in the U.K. by Vision Modular Systems Ltd., which manufactures modules for the construction industry in a controlled assembly-line environment. In the factory, automated production lines transfer the modules through the manufacturing process where internal and some external finishes are applied before the units are shipped. The modules have structural steel frames and solid concrete floors.

High-rise buildings using Vision modules have a reinforced concrete core. The factory-built modules are lifted into place by cranes and seamed together.

One of the company’s projects, College Road in London, England, is comprised of 937 residential units over two towers, 35 and 50 storeys tall. Construction took 32 months.

There are other examples.

In New York City, for instance, the world’s tallest modular hotel, the citizenM Bowery, a 19-storey structure, was built a few years ago by a Dutch company. The building consists of 210 modules, stacked in 15 storeys on a three-storey concrete podium with an underground cellar. The steel-framed modules were shipped to the site in the Lower East Side of New York and then assembled in place.

With Ontario facing a dire shortage of housing, along with the prospect of many workers retiring in the next few years, it is imperative that we find new ways to build homes and condo towers quicker.

There are a myriad of reasons to look at prefab or modular construction.

Modular construction makes economic sense. According to conclusions by architects and engineers in a 2020 report by Dodge Data & Analytics, it has a positive impact on work schedules and budgets, results in improved safety performance, and reduces the waste that is generated by construction.

Panels and modules are built in a controlled factory setting and, when shipped to a site, can be erected and enclosed quickly, with little waste.

With the province setting the ambitious goal of producing 1.5 million homes over the next decade, we must look to new ways of building. Off-site construction certainly fits the bill.